DAIICHI Products: Aluminum Honeycomb Panel

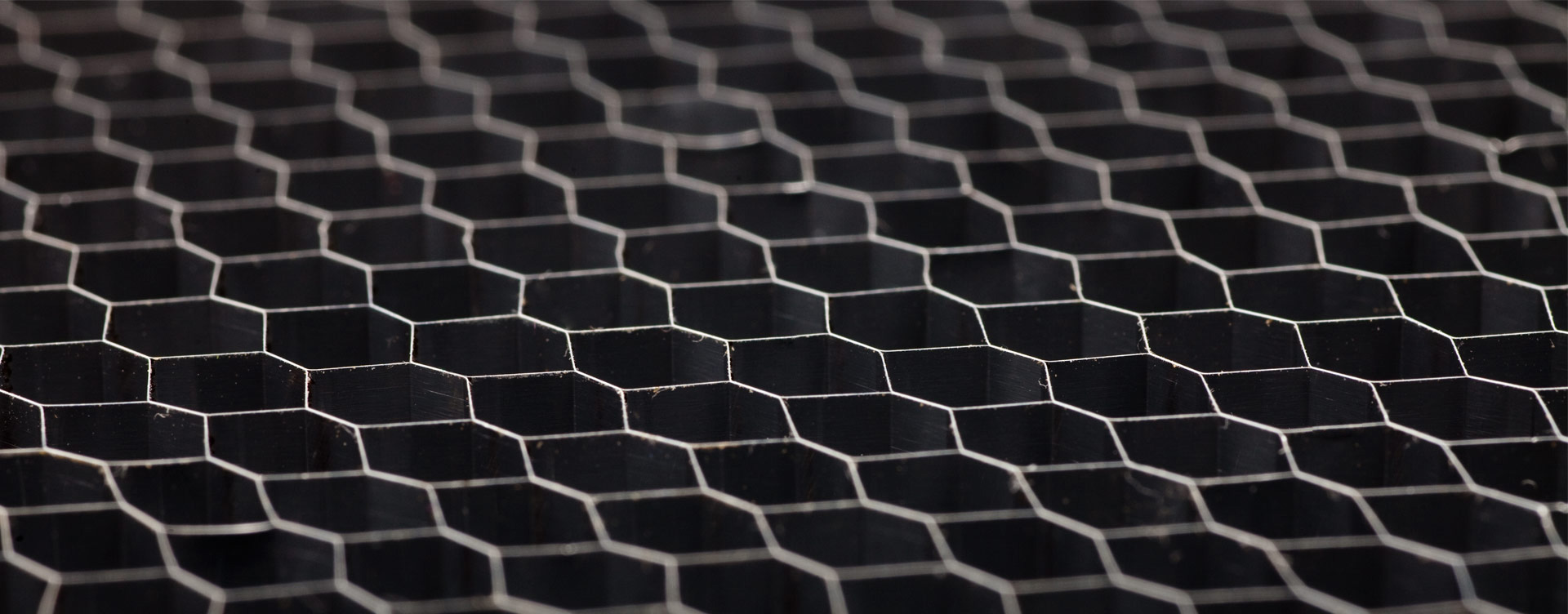

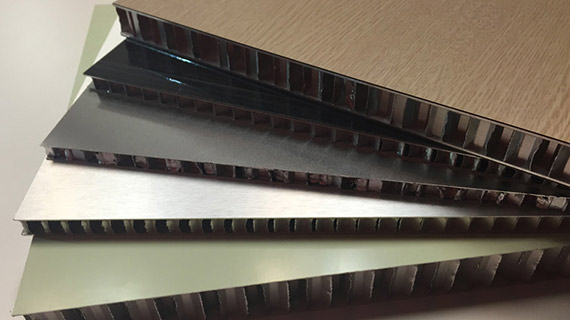

The aluminum honeycomb panel is a sandwich panel consisting of two aluminum plates as surface sheets and hexagonal aluminum honeycomb cells as the core supporting material, bonded together by aviation-purpose epoxy adhesive film. This type of sandwich panel with all usual aluminum panel's advantages and increased rigidity, fire resistance, sound and heat insulation... etc. We can make those honeycomb panel with different coating finishing and widely used in building façades, ceilings, decorations, furniture and more. Moreover, the panel thickness, honeycomb core thickness and honeycomb core height have different specifications, which can meet the different application needs of customers.

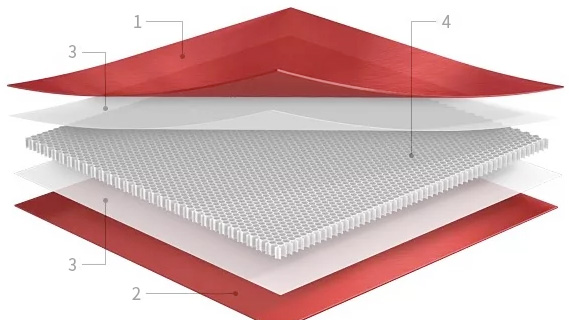

Standard Honeycomb Aluminum Panel Structure

1. Aluminum alloy panel;2. Aluminum alloy panel or other substrate materials;

3. Aviation adhesive;

4. Aluminum alloy honeycomb core.

Curved Honeycomb Aluminum Panel

Honeycomb aluminum panels can be processed into different curved shapes, similar to general aluminum panels, to meet various design needs. The panels can also be coated with faux wood or faux stone, creating curved shapes that are difficult to achieve with real wood or stone.

Honeycomb Aluminum Panel with

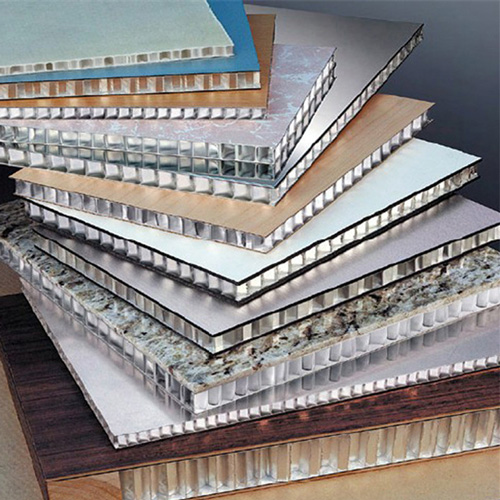

Natural Wood or Stone Veneer

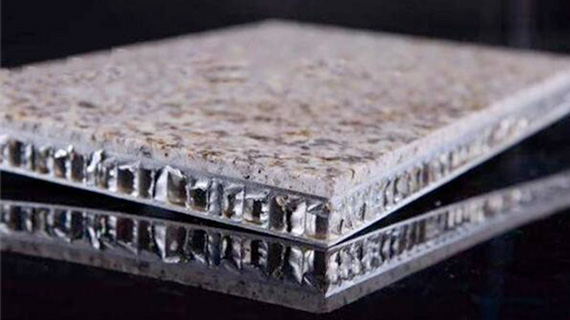

Honeycomb aluminum panels can be veneered with natural wood or stone slices, creating composite materials that combine the advantages of honeycomb aluminum panels with the visual and tactile qualities of natural wood or stone. This makes it an excellent alternative to traditional wood and stone materials.Natural Wood or Stone Veneer

Thermal and Sound Insulation Applications of

Honeycomb Aluminum Panels

Honeycomb aluminum panels have excellent thermal and sound insulation capabilities. They can be combined with materials such as rockwool boards for thermal and sound insulation applications, providing futher better energy efficiency for buildings in different climates.Honeycomb Aluminum Panels